This is a simple project that says how to build a 24x6 led matrix. It is very easy to do this work with low cost and with less period. Because all the components are available for us. Let’s try for a while…

The steps are given below..

Step 1Getting All The Right Things

So there will need the basic set of tools for this project : a soldering iron, some solder wire, a cutter, a needle nosed plier,some wire, wire striper, and some desoldering tools etc..

For the matrix the listed components are needed:

For the matrix the listed components are needed:

For the matrix you will:

1. 144 LEDs

2. 24 resistors( The value is determent by the type of LEDs, in my case 91 ohm)

3. 4017 decade counter

4. 6 1KOhm resistors

5. 6 2N3904 transistors

6. A long Perfboard

7. Arduino

8. 3 x 74HC595 shift register

10. some pin headers

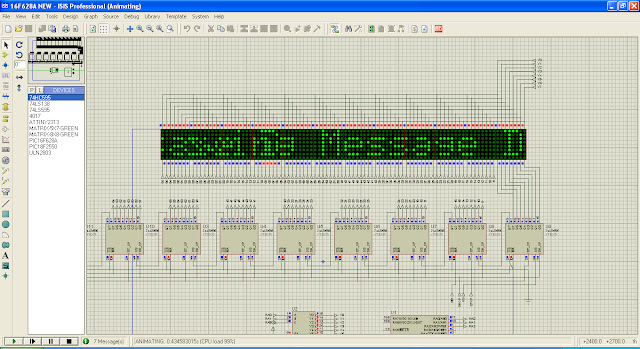

Step 2How it works?

The tricky behind the display is multiplexing and the idea is the same as withe the 8x10 LED matrix: It is basically a way to split information in to little peaces and send it one by one.

this way you can save a lot of pins on the Arduino and keep your program quite simple.

Now this time we have 3 shift registers which multiply the number of outputs and save lots of arduino pins. Each shift register has 8 outputs and you only need 3 arduino pins to control almost an limited numbers of shift registers.

We also use the 4017 decade counter to scan the rows, and you can scan up to 10 rows with it because you have only 10 outputs but to control it you need only 2 pins. The 4017 is a very useful chip and it's a good idea to know how to work with it. Like the scanning is done with the 4017, by connecting one row at a time to ground and sending the right data via the shift registers to the columns.

this way you can save a lot of pins on the Arduino and keep your program quite simple.

Now this time we have 3 shift registers which multiply the number of outputs and save lots of arduino pins. Each shift register has 8 outputs and you only need 3 arduino pins to control almost an limited numbers of shift registers.

We also use the 4017 decade counter to scan the rows, and you can scan up to 10 rows with it because you have only 10 outputs but to control it you need only 2 pins. The 4017 is a very useful chip and it's a good idea to know how to work with it. Like the scanning is done with the 4017, by connecting one row at a time to ground and sending the right data via the shift registers to the columns.

Step 3:

Schematics

The only thing didn't specified in the schematics is the value of the current limiting resistors because they change from each type of LEDs, so it will need to calculate them by ourself.

First there should get some specs on the LEDs, we should know their forward voltage and forward current, these informations are get from the seller. The circuit operates on 5V so the Source voltage is 5V.

There is a added a PCB layout of the control board. It will be very helpful for us.

First there should get some specs on the LEDs, we should know their forward voltage and forward current, these informations are get from the seller. The circuit operates on 5V so the Source voltage is 5V.

There is a added a PCB layout of the control board. It will be very helpful for us.

Step 4:

Soldering The LEDs

Soldering 144 LEDs in a matrix formation can be a little tricky. It is very tough to solder by using lots of wire jumpers. So the above showing methods are more creative to do this.

It is need to bend the positive lead of the LED down towards the other ones and make a column, and snip off the leads that didn't use and try to make the connections as low as we can get, and can be done this to all of the positive leads.

Now the negative leads are connected in a column and thats make soldering tricky because the positive rows are in the way, so it will need to make a 90 degrees bend with the negative lead and make a bridge over the positive row to the next negative lead, and so on to the next LEDs. It is very easy to solder the shift registers and all the parts because every one has hes own style and methods.

Step 5:

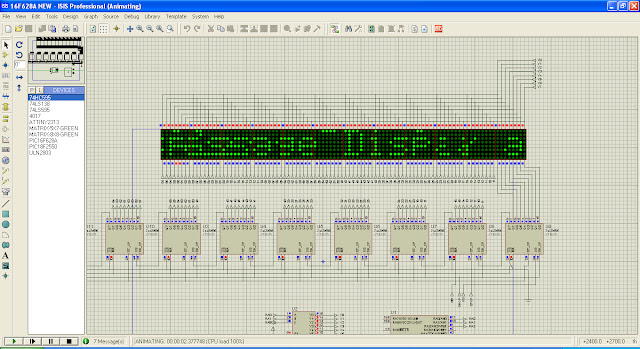

Programming The Display

Now the only thing thats left is the program. So far there are two programs for it that do pretty much the same thing. In the program that gets a word or a sentence from the arduino IDE serial monitor and displays it on the matrix, the code is very basic and may be not the best in the world but it does the work, and it is free to write our own code and modify mine as we wish.

In the excel file we can create our own symbols and characters.

The way it works is like so:

First create the symbol that want pixel by pixel(don't worry it's very easy) and copy the output line like so - #define {OUTPUT LINE}.

In the excel file we can create our own symbols and characters.

The way it works is like so:

First create the symbol that want pixel by pixel(don't worry it's very easy) and copy the output line like so - #define {OUTPUT LINE}.

Thus the work had done successfully. Now the 24x6 LED is ready to work.

I discard pages heavily printed, preferring pages with normal-size text on white background. Although ink usually does not transfer on the PCB, heavy print of headlines sometimes accumulate so much ink that some gets on copper.

I discard pages heavily printed, preferring pages with normal-size text on white background. Although ink usually does not transfer on the PCB, heavy print of headlines sometimes accumulate so much ink that some gets on copper. Laser printers are not designed for handling thin, cheap paper, so we must help them feeding the sheets manually instead of using the paper tray. Selecting a straight paper path minimizes the chances of clogging. This is usually achieved setting the printer as if it were printing on envelopes.

Laser printers are not designed for handling thin, cheap paper, so we must help them feeding the sheets manually instead of using the paper tray. Selecting a straight paper path minimizes the chances of clogging. This is usually achieved setting the printer as if it were printing on envelopes.